Plush toys have their own unique methods and standards in technology and production methods. Only by understanding and strictly following its technology, can we produce high-quality plush toys. From the perspective of large frame, the processing of plush toys is mainly divided into three parts: cutting, sewing and finishing.

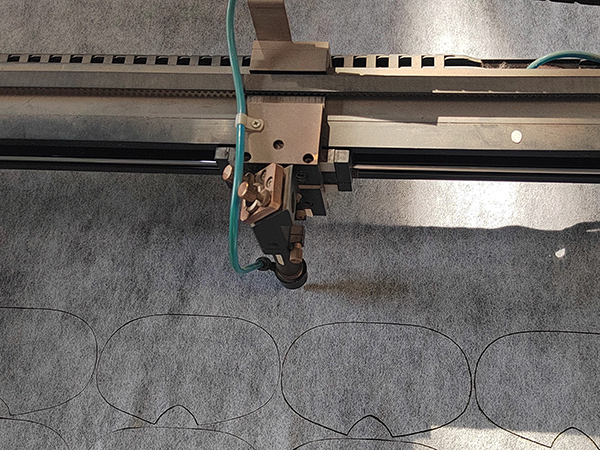

The following three parts explain the following contents: first, clipping. Traditional cutting methods mainly include hot cutting and cold cutting. Now some factories have begun to use laser cutting. Different fabrics can be customized according to different cutting methods. Cold cutting not only uses steel grinding tools and presses to press toy fabrics, but also is suitable for multi-layer cutting of thinner fabrics, with high efficiency. Thermal cutting is a plate mold made of gypsum board and hot fuse. After power on, the cut toy fabric is blown. This thermal cutting method is more suitable for fabrics with thick chemical fiber types, and multi-layer cutting is not allowed. When cutting, we should pay attention to the hair direction, color difference and the number of fragments of the toy fabric. Cutting must be scientific layout, which can save a lot of fabric and avoid unnecessary waste.

2. Sewing

This part of sewing is to splice the cutting parts of the toy together to form the basic shape of the toy, so as to facilitate the later filling and finishing, and finally complete the product. Everyone on the production line knows that in the sewing process, the alignment of sewing size and marking points is very important. The splicing size of most toys is 5mm, and some small toys can use 3mm seams. If the stitch size is different, it will appear. Deformation or asymmetry, such as the size of the left leg is different from that of the right leg; If the stitching of the marked points is not aligned, it will appear, such as limb distortion, face shape, etc. Different toy fabrics should be used with different needles and needle plates. Thinner fabrics mostly use 12 # and 14 # sewing machine needles and eyelet needle plates; Thick fabrics usually use 16 # and 18 # needles, and use large eye plates. Always pay attention to the fact that jumpers should not appear during sewing. Adjust the stitch code for toy pieces of different sizes, and pay attention to the integrity of the stitch. The starting position of the suture should pay attention to the backing of the needle and avoid the opening of the suture. In the process of sewing toys, the quality inspection of the sewing team, the reasonable layout of the assembly line, and the effective use of auxiliary workers are the keys to improve efficiency and strict quality. Regular oiling, cleaning and maintenance of sewing machines should not be ignored.

3. After completion

In terms of the type of process and equipment, the finishing process is relatively complex. After completion, there are stamping, turning, filling, seam, surface processing, forming, blowing, thread cutting, needle inspection, packaging, etc.; The equipment includes air compressor, punching machine, carding machine, cotton filling machine, needle detector, hair dryer, etc. Pay attention to the model and specification of the eye when drilling. The tightness and tension of eyes and nose should be tested; When filling, pay attention to the fullness, symmetry and position of the filling parts, and weigh each product with a weighing tool; Some toy seams are on the back. For sealing, pay attention to the size of pins and bilateral symmetry. No obvious needle and thread traces can be seen at the position after stitching, especially for some short pile hot thin materials, the joints cannot have too large joints; The charm of plush toys is often concentrated on the face, so the manual and careful treatment of the face is very important, such as face fixation, pruning, nose manual embroidery, etc.; A high-quality plush toy needs to finish the shape, remove the thread, connect the hair, check and pack the needle. Many post-processing workers with many years of experience can be called modification craftsmen, and can modify some problems in the previous process. Therefore, experienced old workers are the precious wealth of the factory.

Post time: Jul-22-2022